Winter: a season that often evokes thoughts of cosy evenings and festive holidays. Yet, for those involved in the construction industry, particularly plant managers and operators, winter can present an array of unique challenges. Cold and wet conditions have a significant impact on both plant machinery and the operators who handle them. From slippery surfaces to frozen controls, the winter months require an extra level of attention to detail to maintain a safe and efficient work environment.

This comprehensive guide aims to shed light on the various hurdles that colder weather brings to the construction site. Whether you’re operating excavators, dumpers or other crucial equipment, knowing how to prepare and respond to winter conditions is vital. In the following sections, we’ll explore the risks, safety precautions and best practices for managing plant and machinery during this challenging season.

Beyond practical advice, this guide will also introduce you to how Rabbit & Dowling Plant Hire can support you in overcoming these winter challenges. With a range of plant hire equipment suitable for various applications and weather conditions, our expert team is here to help you navigate winter’s icy grip.

The Risks of Cold Weather on Plant Machinery

Cold and wet winter conditions pose an array of challenges for plant machinery. Lower temperatures can affect the performance, longevity and reliability of vital equipment like excavators, dumpers and rollers. Let’s delve into the specific issues you might encounter and what risks you should keep in mind.

Impact on Excavators, Dumpers and Other Key Equipment

The cold weather can lead to a decrease in hydraulic fluid efficiency, making it more difficult for machinery like excavators and dumpers to operate smoothly. Moreover, icy or snowy conditions may make ground surfaces slippery, affecting the mobility and stability of these heavy machines. This is especially true for equipment without tracks, which can find it increasingly challenging to gain the necessary traction.

Signs of Weather-Related Wear and Tear

In colder conditions, watch for an increased incidence of rust and corrosion, particularly on exposed metal surfaces. Low temperatures can also make rubber and plastic components brittle, increasing the risk of cracks or fractures. Such damage not only compromises performance but also raises the risk of sudden equipment failure.

Best Practices for Plant Maintenance in Winter

Winter conditions necessitate a heightened focus on plant machinery maintenance. The challenges are numerous, but with the right strategies and awareness, you can ensure that your equipment remains in optimal condition. Below are some key best practices to consider.

The importance of regular checks

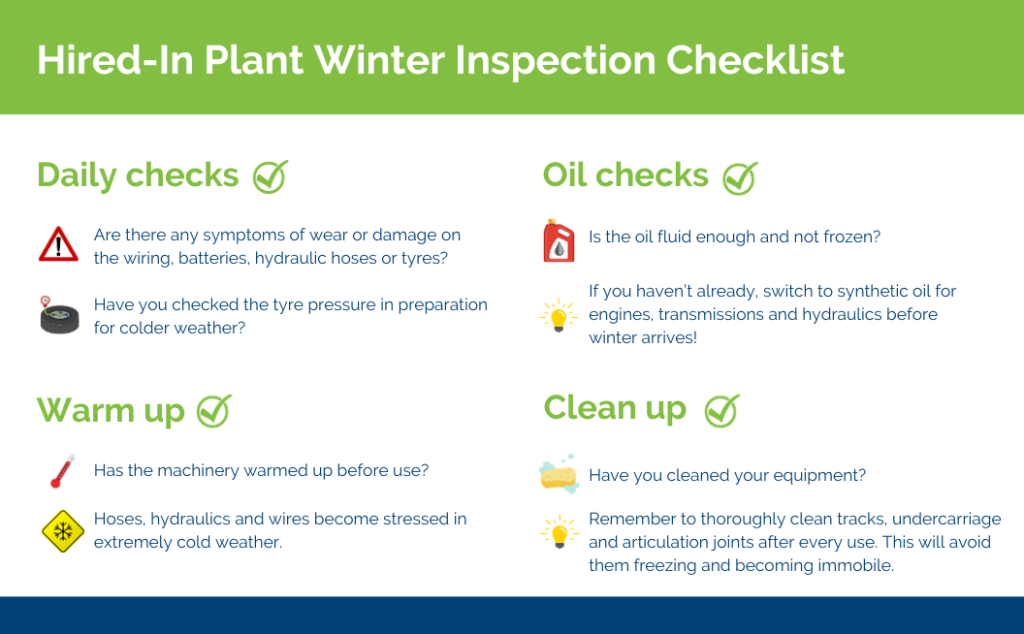

Regular inspections are crucial, especially when temperatures drop. Make it a routine to assess the mechanical and hydraulic components for wear and tear or signs of frost damage. Take note of any discrepancies in performance, strange noises or unusual vibrations that could signal underlying issues.

Lubrication and fluid levels

Maintaining the right lubrication levels is essential for the smooth operation of plant machinery. Winter-grade lubricants can withstand lower temperatures and provide better protection. Check the fluid levels frequently and consider using antifreeze additives to prevent hydraulic fluids from thickening in the cold.

How do I prepare and care for plant and machinery in cold/wet conditions?

Preparation begins with a thorough inspection of all equipment. Ensure that batteries are fully charged, tyres are inflated to the correct levels and all lighting and signals are operational. Cold conditions can exacerbate minor issues, turning them into major problems, so make sure that all repairs are completed before winter sets in.

What is a winter maintenance plan?

A winter maintenance plan is a comprehensive document outlining all the procedures, checks and necessary steps to prepare and maintain your plant machinery for winter. This plan should be easily accessible and regularly updated, serving as a go-to guide for operators and managers alike.

By adhering to these best practices, you not only extend the lifespan of your machinery but also contribute to a safer and more productive work environment. Taking the time to carry out these checks may seem laborious, but the long-term benefits, in terms of reduced downtime and fewer repairs, are invaluable.

The Advantages of Hiring Plant and Machinery for Winter Operations

When winter comes around, construction projects often require extra care and preparation. One solution that offers flexibility and a range of benefits is to hire plant and machinery. Let’s explore how this approach can help you meet the demands of the colder months.

Flexibility and customisation

The winter season may necessitate specific types of machinery that you don’t normally use. Hiring allows you to choose from a wide variety of equipment, tailored to your project’s requirements. For instance, tracked dumpers might be more suitable for icy terrain compared to wheeled ones.

Hassle-free maintenance

When you hire from a reputable company like Rabbit & Dowling Plant Hire, the equipment often comes with comprehensive maintenance support. This means that you don’t have to worry about winter-specific upkeep, as this is taken care of by experts who are familiar with the seasonal demands on plant machinery.

How does hiring in plant and machinery help mitigate the challenges of winter construction?

Hiring offers the advantage of utilising well-maintained and season-ready machinery. It also provides a financial benefit, as you don’t incur the full cost of purchasing equipment that may only be needed for a limited time. Plus, it frees up capital for other crucial aspects of your project, like materials and labour.

Streamlined operations

By hiring equipment tailored to winter conditions, you streamline your operations and improve efficiency. You won’t lose time attempting to adapt ill-suited machinery for winter tasks, allowing your team to focus on the construction at hand.

Risk mitigation

Hiring allows you to benefit from the latest safety features and technologies, thus reducing the risk of accidents and breakdowns. It also means you can easily switch out equipment if any issues do arise, minimising delays.

Opting for plant hire during winter can make a substantial difference in how smoothly your project runs. Not only does it offer operational and financial flexibility, but it also comes with the peace of mind of knowing that you’re working with machinery fit for the season.

Conclusion: Meeting Winter Challenges Head-On

Winter brings a unique set of challenges to the construction industry, particularly for those responsible for operating and managing plant and machinery. From adapting to cold and wet conditions, to ensuring the safety of operators, the colder months require meticulous planning and proactive management.

Braving the elements successfully is more than possible with careful preparation. Whether it’s implementing safety precautions, adopting a well-defined winter maintenance plan, or considering the option of hiring specialised machinery, these measures collectively contribute to a more streamlined and secure construction environment.

Remember, preparation is the key to overcoming winter challenges. We at Rabbit & Dowling Plant Hire are always here to help, offering a wide range of plant hire options suitable for winter projects, along with the expertise to ensure you select the right equipment for your needs.

Face winter’s trials with confidence, knowing that, with the right approach, your construction projects can proceed smoothly, efficiently, and above all, safely.

Rabbit Plant Hire:

Rabbit & Dowling Plant Hire is an established and expert supplier of plant hire for commercial and domestic building projects throughout Sussex, Surrey and Hampshire.

To find out more about Rabbit & Dowling Plant Hire’s plant hire services contact our expert and friendly team on 01903 851957 or info@rabbitanddowling.co.uk.

Rabbit & Dowling Plant Hire is part of The Rabbit Group of companies, which includes Rabbit Demolition, Rabbit Skip Hire and Rabbit Toilet Hire.