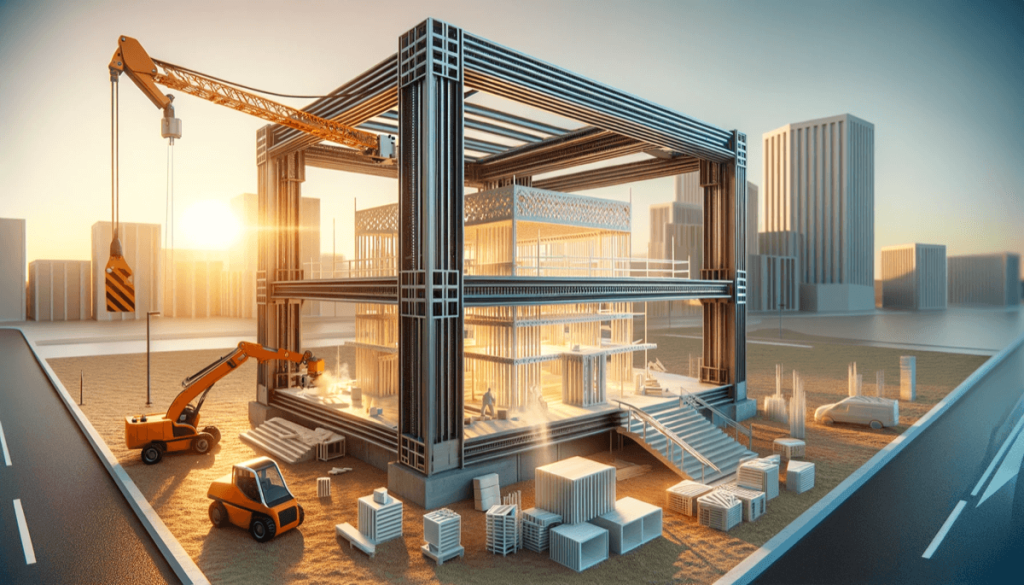

In an industry as dynamic and foundational as construction, staying ahead of the curve is not just an advantage – it’s a necessity. The latest surge in technological advancements is setting a new paradigm in how we approach building and infrastructure development. This exciting juncture in the construction industry is marked by a wave of innovative trends, each promising to transform the way we think about construction projects.

From the depths of excavation sites to the heights of skyscrapers, new technologies are reshaping the landscape of construction. Autonomous machinery and robotics are no longer just figments of a futuristic imagination; they are current realities, enhancing precision and safety on-site. Drones, once a novelty, now play a pivotal role in surveying and monitoring, offering a bird’s-eye view that ensures accuracy and efficiency. The potential of 3D printing in construction is unfolding rapidly, paving the way for more environmentally friendly and cost-effective building methods.

As we delve into the world of modern construction technology, it’s clear that these advancements are not just incremental improvements; they are transformative shifts that promise to elevate the construction industry to new heights of innovation and efficiency. This blog post aims to explore these cutting-edge trends, providing insights into how they are changing the face of construction and what the future might hold for this ever-evolving industry.

Autonomous Machinery and Robotics in Construction

The construction industry is witnessing a significant transformation with the integration of autonomous machinery and robotics. This technological leap is not just a trend but a foundational shift, shaping the future of construction processes and methodologies.

Autonomous Machinery: Enhancing Efficiency and Safety

Autonomous machinery, equipped with sensors and GPS technology, operates with precision and consistency. These self-guided machines, ranging from excavators to bulldozers, have the capability to perform tasks such as digging, grading and loading with minimal human intervention. This automation not only increases efficiency but also significantly reduces the margin of error, leading to more accurate outcomes.

The safety benefits are equally compelling. Autonomous machinery minimises the need for human workers to be in potentially hazardous environments. This not only reduces the risk of accidents but also alleviates physical strain on workers, ultimately leading to healthier work conditions.

Robotics: Precision and Innovation on the Construction Site

Robotics in construction extends beyond mere automation. Advanced robotic arms, for example, can perform complex tasks like welding, painting and material handling with a level of precision that surpasses human capabilities. These robots can work tirelessly, ensuring project deadlines are met without compromising quality.

Moreover, robotic technology is evolving to include collaborative robots, or ‘cobots’, which work alongside human workers, enhancing their capabilities rather than replacing them. These cobots can assist with lifting heavy materials or performing repetitive tasks, allowing human workers to focus on more skilled aspects of the project.

The integration of autonomous machinery and robotics in construction is not a fleeting trend but a pivotal development. By embracing these technologies, construction projects can achieve unprecedented levels of precision, efficiency, and safety. As we continue to explore and implement these innovations, the construction industry stands on the brink of a new era, marked by technological excellence and improved project outcomes.

Drone Technology and Digital Twins in Construction

The use of drone technology and the concept of digital twins are rapidly becoming integral components of modern construction projects. These technologies are not just enhancing existing practices; they are shaping the way we plan, monitor and execute construction projects.

Drones: A Bird’s-Eye View for Precision and Efficiency

Drones, or unmanned aerial vehicles (UAVs), are increasingly being used in construction for a variety of tasks, including aerial surveying, site inspections and progress monitoring. Equipped with high-resolution cameras and sensors, drones provide a comprehensive view of the construction site, capturing details that might be missed from the ground.

This bird’s-eye perspective is invaluable for accurate site analysis, mapping and planning. Drones can quickly survey a large area, providing real-time data that helps in making informed decisions. They are particularly useful in hard-to-reach areas, reducing the risk and cost associated with traditional surveying methods.

Digital Twins: Revolutionising Project Management

A digital twin is a virtual representation of a physical construction project. It uses data collected from various sources, including drones, sensors and other IoT devices, to create a dynamic, 3D model of the construction site. This model can be used for simulation, analysis and remote monitoring, offering a powerful tool for project management.

Digital twins allow for better planning and decision-making. By simulating different scenarios, project managers can anticipate potential issues and make adjustments before they impact the construction process. This proactive approach leads to increased efficiency, reduced costs, and improved project outcomes.

The integration of drone technology and digital twins in construction is a testament to the industry’s ongoing evolution. These technologies offer significant advantages in terms of efficiency, accuracy, and project management. As we continue to harness their full potential, they are set to become standard practices in the construction industry, shaping the future of construction project execution.

3D Printing and Innovative Materials in Construction

The advent of 3D printing technology, along with the use of innovative materials, is setting new benchmarks for efficiency, sustainability, and design flexibility in construction.

3D Printing: Reshaping Construction Methodologies

3D printing, also known as additive manufacturing, is rapidly transforming the way buildings are constructed. This technology allows for the creation of complex building structures layer by layer, using a variety of materials, including concrete, plastic, and metal. The advantages of 3D printing in construction are manifold:

- Efficiency and Speed: 3D printing significantly speeds up the construction process. Components can be printed off-site and assembled on-site, reducing the overall project timeline.

- Cost-Effectiveness: This technology minimises waste by using only the necessary amount of material, leading to cost savings on materials and labour.

- Design Freedom: 3D printing enables architects and designers to experiment with complex, innovative designs that would be difficult or impossible to achieve with traditional construction methods.

- Sustainability: The ability to use eco-friendly materials in 3D printing makes it a sustainable option for the environmentally conscious construction sector.

Innovative Materials: Paving the Way for Sustainability

Alongside 3D printing, the use of innovative materials is redefining construction. These materials are not just about strength and durability; they also focus on sustainability and environmental impact. Examples include:

- Self-healing Concrete: Concrete that can repair its own cracks, significantly increasing the lifespan of a structure.

- Aerogels: Extremely light yet strong materials used for insulation, enhancing energy efficiency in buildings.

- Transparent Aluminium: A new material offering the aesthetics of glass with the strength of metal, ideal for modern architectural designs.

The incorporation of 3D printing technology and innovative materials is more than just a trend; it’s a paradigm shift in the construction industry. These advancements are not only enhancing the way we build but also ensuring that construction practices become more sustainable and cost-effective. As these technologies continue to evolve, they hold the promise of shaping the future of construction, opening doors to possibilities that were once deemed unattainable.

Augmented and Virtual Reality in Construction

The construction industry is entering a new era of digital innovation with the adoption of Augmented Reality (AR) and Virtual Reality (VR) technologies. These tools are not just enhancing the visualisation process; they are revolutionising the way construction projects are planned, executed, and delivered.

Augmented Reality: Enhancing Real-World Interactions

AR technology overlays digital information onto the physical environment, offering a unique interactive experience. In construction, AR can be used in various ways:

- Project Visualisation: AR enables stakeholders to visualise the end product in a real-world context, providing a clear understanding of the design and structure before construction begins.

- On-Site Navigation: Construction workers can use AR for accurate on-site navigation and understanding complex elements of the project, reducing errors and increasing efficiency.

- Training and Safety: AR offers an interactive platform for training workers, helping them understand complex processes and machinery, which in turn enhances on-site safety.

Virtual Reality: Immersive Planning and Design

VR takes this a step further by creating a completely immersive, interactive 3D environment. In construction, VR’s applications are extensive:

- Design and Planning: VR allows architects and engineers to walk through virtual models of their designs, identifying potential issues and making adjustments before construction starts.

- Client Engagement: Clients can experience a virtual representation of their project, providing feedback and making decisions before any physical work is done.

- Collaboration: VR enables remote teams to collaborate effectively, discussing and modifying designs in a virtual space, regardless of their physical location.

The integration of AR and VR technologies in construction represents a significant leap forward in project management and execution. These technologies not only enhance the efficiency and accuracy of construction projects but also provide an immersive and interactive experience for everyone involved. As AR and VR continue to evolve, they are set to become indispensable tools in the construction industry, shaping the way we build our future.

Predictive Analytics and Cloud-Based Collaboration in Construction

The construction industry is increasingly turning to digital solutions to enhance efficiency and decision-making. Two such transformative technologies are predictive analytics and cloud-based collaboration tools. These digital advancements are proving to be game-changers in managing construction projects.

Predictive Analytics: Anticipating Challenges and Opportunities

Predictive analytics involves analysing data to forecast future events and trends. In the context of construction, this technology is used to:

- Risk Mitigation: By analysing historical data, predictive analytics can identify potential risks and challenges, allowing for proactive measures to avoid costly delays and accidents.

- Resource Optimisation: It helps in efficient resource allocation by predicting the required manpower, materials, and machinery, ensuring that projects stay on budget and on schedule.

- Quality Control: Predictive models can foresee quality issues, allowing for immediate corrective actions to maintain the highest standards.

Cloud-Based Collaboration: Enhancing Communication and Efficiency

Cloud-based collaboration tools have revolutionised how construction teams communicate and work together. These tools offer numerous benefits:

- Real-Time Communication: Team members can share updates, documents, and feedback in real time, ensuring everyone is on the same page.

- Accessibility: Cloud-based tools can be accessed from anywhere, providing flexibility and facilitating remote work.

- Data Integration: They allow for the integration of different data sources, providing a comprehensive view of the project and aiding in informed decision-making.

The adoption of predictive analytics and cloud-based collaboration tools in construction signifies a major shift towards data-driven, connected project management. These technologies not only streamline processes but also enhance the accuracy and efficiency of construction projects. As the construction industry continues to embrace these digital solutions, we can expect to see more innovative, cost-effective, and successful projects being delivered.

Embracing Technology – The Future of Construction

As we have explored, the construction industry is on the cusp of a technological revolution. The emergence of autonomous machinery, the widespread use of drones, the innovative approaches of 3D printing, and the incorporation of augmented and virtual reality, along with predictive analytics and cloud-based collaboration, are not just trends. They are powerful forces reshaping the very foundation of construction methodologies.

The future of construction is bright and laden with possibilities. These technologies are setting new standards for efficiency, safety, and innovation. As the industry continues to evolve, it is crucial for professionals and companies to embrace these advancements. Staying ahead in this technological race is not just about competitive advantage; it’s about redefining what’s possible in construction.

The integration of these technologies will lead to smarter, faster, and more sustainable construction practices. It’s an exciting time for the industry and Rabbit Plant eagerly anticipates the advancements and innovations that the future of construction technology will bring.

Rabbit & Dowling Plant Hire is an established and expert supplier of plant hire for commercial and domestic building projects throughout Sussex, Surrey and Hampshire.

To find out more about Rabbit & Dowling Plant Hire’s plant hire services contact our expert and friendly team on 01903 851957 or info@rabbitanddowling.co.uk.

Rabbit & Dowling Plant Hire is part of The Rabbit Group of companies, which includes Rabbit Demolition, Rabbit Skip Hire and Rabbit Toilet Hire.